We have one of the biggest manufacturing plant in Eastern India. Our two unit in Howrah, West Bengal companies of

area more than 100000 sq. ft. The area includes cold & hot manufacturing of machine fasteners, pole line hardware,

hot dip galvanizing, and laboratory for continuous scrutiny of quality. We have strong work force of 250 employees

including skilled and semi-skilled workers.

The company manufacturing plant is equipped with all the modern technologies to facilate efficient production.

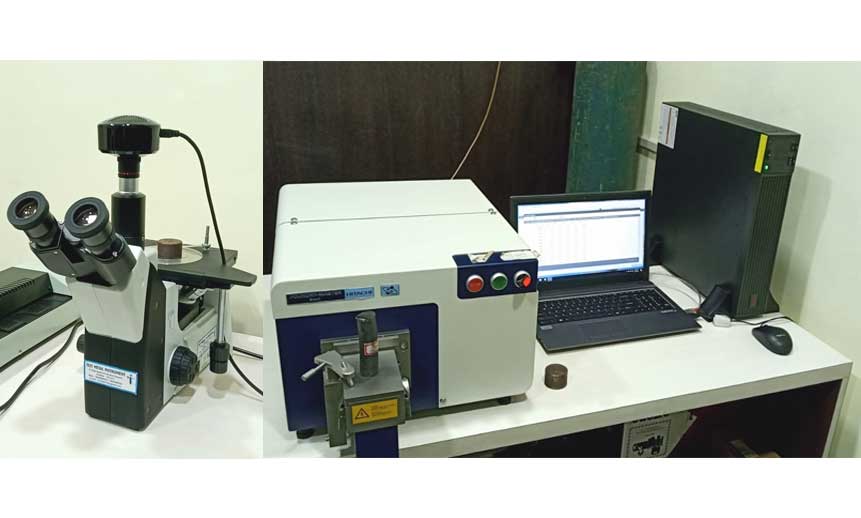

Usha Power & Transmission Pvt. Ltd. have sufficient in house testing laboratory equipment certified by NABL to carry

out all type acceptance and routine tests on all types of Pole Line Hardware fittings, Transmission & Distribution

accessories as per ANSI, ASTM, DIN , BS, IS, CSA standard specification by well qualified and experienced Engineers

and Technician.

We have an experienced team for drawing products confirminh to ASTM/BS/IS standard using AutoCAD.

Our Process includes:- Planning Conceptualization Detailing Verification & Validation of Designs Proto Testing Acceptance.